February 16, 2012 - Washington, DC Overview and Agenda Photos

The Modeling and Simulation Behind Improving Everyday Life

![]() Download Summary

Download Summary

![]() Download PDF Slides

Download PDF Slides

![]() Download Video

Download Video

Summary

Procter & Gamble, founded in 1837, manufactures products and services that touch the lives of four billion consumers every year. Investors know P&G as a company with $82 billion in sales and $12 billion in net earnings. P&G has paid dividends continuously since 1890 and for 55 years has increased them at an annual compound average rate of about 9.5 percent. It has a market capitalization of approximately $180 billion. As a long-time employee, I can explain how the fruits of research have made that possible.

Most people know P&G by our brands. Twenty-three brands have sales in excess of $1 billion. Brands like Tide™, Gain™, and Downy™ are in our long-established "Laundry" category; Head & Shoulders™, Pantene™, Olay™, Gillette™, Braun™ lead our "Beauty and Grooming" categories; we were pioneers in oral health with Crest™ and Oral-B™; and Bounty™, Charmin™ and Pampers™ have improved the lives of families for decades. Pampers alone has netted over $8 billion in sales.

Innovation is P&G's lifeblood and we invest more than $2 billion each year in research and development. So, why does making life a little better for four billion of the world's population demand "Rocket Science"? One way we innovate is by delivering breakthrough performance by mastering technical contradictions. For example, we make paper and absorbent materials that are strong but soft; breathe but contain fluid; break but don't tear; and stretch but don't break. In our packaging, we want strong but limited waste material, and liquid containers that never leak but yet open easily. We want laundry formulations that protect fabric but remove stains and soil; that are concentrated but dispensed easily. We want formulated liquid mixtures like Olay™ and Crest™ that don't separate on the shelf; that dispense easily but stay where applied. The way we attain the desired properties of our products is through simulation - the classic "Rocket Science".

Another "rocket science" challenge of serving four billion people is the scale of manufacturing. Unlike submarines, jet engines or even mining vehicles (all of which are notably high-tech and generate over $1 billion in revenue), we manufacture about two billion diapers to make $1 billion. In our manufacturing systems, that takes only days.

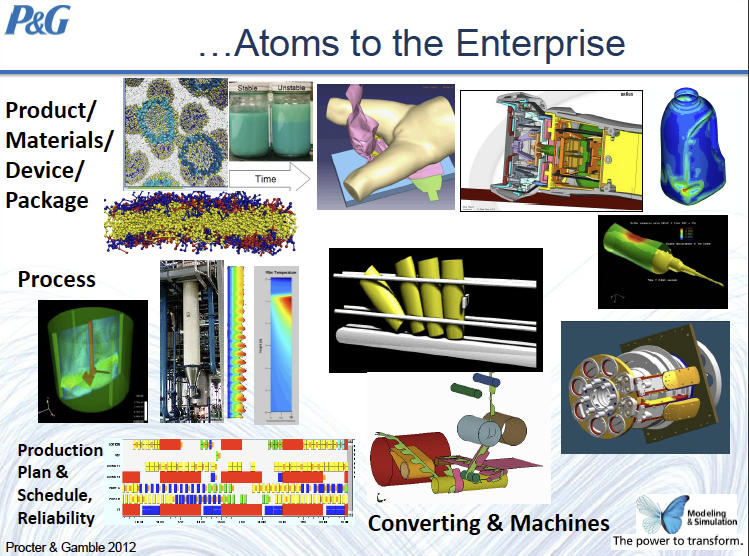

These challenges led us to collaborate with some of the world's best scientists and engineers. We have worked with colleagues at Los Alamos National Lab since 1993 on more than a dozen Cooperative Research and Development Agreements (CRADAs), with more than $20 million Funds-In plus equal matching In-Kind. The work has resulted in excess of several billion in real value. In addition, P&G has worked with Sandia National Laboratory, Oak Ridge National Laboratory, Argonne National Laboratory, Pacific Northwest National Laboratory, the NSF-funded National Center for Supercomputing Applications (NCSA) located at the University of Illinois at Urbana-Champaign, and several NSF Engineering Research Centers (ERCs). We are a two-time awardee of the Department of Energy's Innovative and Novel Computational Impact on Theory and Experiment (INCITE) program. Shown in the image are numerous examples of modeling and simulation applied to our products, processes and production systems, often the result of these collaborations.

Modeling and simulation in the future will need to:

-

Tackle "bigger," more complex problems more completely, i.e., solving larger equation sets;

-

Replace point estimate calculations, with parametric studies; and

-

Democratize analysis to non-analysts e.g. "Turbo Tax©" complexity.

Tom Lange

Tom Lange has a BSChE degree from the University of Missouri-Columbia. He joined The Procter & Gamble Company in May 1978 as a product technical engineer. In his first assignment, while supporting Jif Peanut Butter Manufacturing, Mr. Lange built models of Cyclone Separators and Fluid Bed Roasters, beginning a 34-year career in Modeling and Simulation. Through Test Market and National rollout with plant start-ups in Duncan Hines Ready-to-Serve Chocolate Chip Cookies, Consumer Acceptance, Formulation, and Process models became part of the assignment. In 1987, Mr. Lange moved to Baby Diapers with both quality and reliability responsibilities that were heavily Modeling and Simulation-based. In 1999, he founded the MS&A (Modeling, Simulation and Analysis) Department at P&G Company. He began his current role, in 2004, as the Director, Modeling & Simulation, R&D, with the Global Capability Organization forming in 2008. In this role, Mr. Lange leads P&G's Modeling & Simulation efforts ranging from Computational Chemistry & Biology, Consumer Modeling, to Computer Aided Engineering (CAE) Structural & Dynamic, Fluids & Thermal, Dynamics & Controls, Chemical Systems, Empirical & Optimization, Should Cost Analysis, Reliability, Throughput and Supply Chain Analysis.

Tom Lange has a BSChE degree from the University of Missouri-Columbia. He joined The Procter & Gamble Company in May 1978 as a product technical engineer. In his first assignment, while supporting Jif Peanut Butter Manufacturing, Mr. Lange built models of Cyclone Separators and Fluid Bed Roasters, beginning a 34-year career in Modeling and Simulation. Through Test Market and National rollout with plant start-ups in Duncan Hines Ready-to-Serve Chocolate Chip Cookies, Consumer Acceptance, Formulation, and Process models became part of the assignment. In 1987, Mr. Lange moved to Baby Diapers with both quality and reliability responsibilities that were heavily Modeling and Simulation-based. In 1999, he founded the MS&A (Modeling, Simulation and Analysis) Department at P&G Company. He began his current role, in 2004, as the Director, Modeling & Simulation, R&D, with the Global Capability Organization forming in 2008. In this role, Mr. Lange leads P&G's Modeling & Simulation efforts ranging from Computational Chemistry & Biology, Consumer Modeling, to Computer Aided Engineering (CAE) Structural & Dynamic, Fluids & Thermal, Dynamics & Controls, Chemical Systems, Empirical & Optimization, Should Cost Analysis, Reliability, Throughput and Supply Chain Analysis.

The materials on this webpage, including speakers' slides and videos, are copyright the author(s).

Permission is granted for non-commercial use with credit to the author(s) and the Computing Community Consortium (CCC).